In the field of construction machinery, hydraulic oil pipe burst has always been a tricky problem faced by excavator masters. Sudden bursting of hydraulic pipe will not only lead to serious leakage of hydraulic oil, affecting the normal operation of the machine, but also bring great inconvenience and cost to the subsequent maintenance work. For this reason, we have discussed in depth the common causes of hydraulic pipe burst, and provide efficient remedial measures, aiming to help the majority of excavator masters to better cope with this problem.

Hydraulic pipe burst seven major reasons

1. The use of poor quality hydraulic pipes: many masters in the original hydraulic pipe damage, in order to save costs, choose the quality of substandard hydraulic pipes. The performance and reliability of these hydraulic pipes is far less than the original product, easy to use in the use of problems.

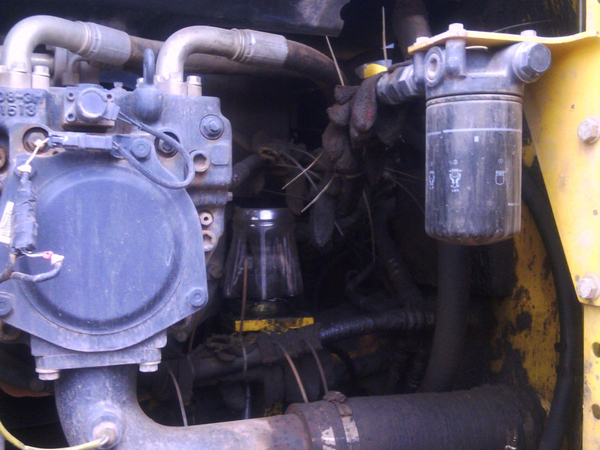

2. Hydraulic system pressure is too high: hydraulic system preset pressure is too high will greatly increase the chance of pipe burst. By testing the pressure value generated by the main pump, and properly adjust the pressure of the multi-way valve can effectively reduce the risk of pipe burst.

3. Hydraulic oil temperature is too high: high temperature will not only affect the sealing of hydraulic components, but also lead to the expansion of hydraulic parts, which in turn triggered the burst pipe. Therefore, it is critical to maintain the appropriate temperature of the hydraulic system.

4. Mixed use of different grades of hydraulic oil: excavators factory default use a specific grade of hydraulic oil, mixed use of different grades of hydraulic oil will lead to unstable properties of hydraulic oil, damage to components.

5. bad operating habits: rough operation will produce instantaneous shock pressure in the hydraulic system, which will lead to pipe burst. Therefore, gentle operating habits are essential to extend the service life of hydraulic tubes.

6. Hydraulic tube corrosion: Although modern hydraulic tubes have a certain degree of corrosion resistance, long-term exposure to corrosive liquids such as diesel fuel will lead to colloidal deterioration. Therefore, diesel and other liquids should be avoided in the process of use contact with the hydraulic tube.

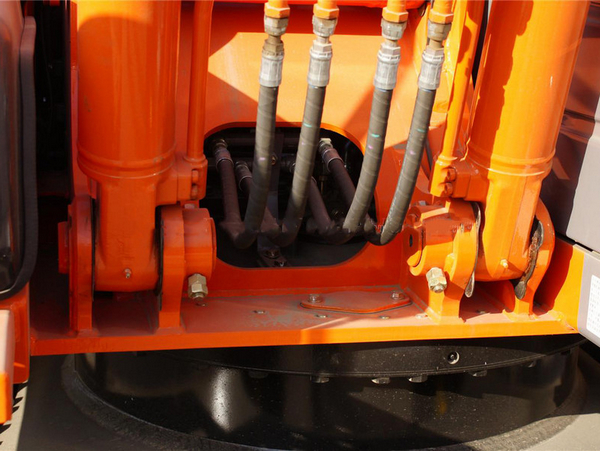

7. Hydraulic tube abnormal vibration: hydraulic tube in the working process will produce high-frequency vibration, long-term abnormal vibration will lead to hydraulic tube fatigue wear. Therefore, it is vital to check the clamps and protective sleeves of the hydraulic hose regularly.

Efficient Remedy

When a hydraulic pipe burst occurs, in order to avoid excessive loss of hydraulic oil, the bucket should first be landed on the ground, and then shut down and switch off the engine to reduce the pressure in the hydraulic system. If construction site conditions prevent immediate replacement of the hydraulic pipe, the following temporary remedial measures can be taken:

1. Sticky patch method: For the rupture of rubber hose with pressure between 25-8.0MPa, the sticky patch method can be used. Wipe clean around the rupture, apply the appropriate glue, and use tape or cloth to wrap around the glue coated place several layers, in order to play a temporary sealing effect.

2. Hose swap method: in some excavators, loaders in the hydraulic system, the same oil circuit of the rubber hose specifications are the same but different oil pressure. Can be ruptured oil hose and not ruptured oil hose interchangeable use, that is, not ruptured oil hose to withstand high pressure, with the oil hose has been broken but after a simple sticky patch or bundled to withstand low pressure.

However, it should be noted that the above method is only as a temporary emergency remedy, the hydraulic pipe performance will be reduced. Therefore, replace the hydraulic pipe with a new one and replenish the hydraulic oil as soon as possible when conditions permit.